载

大

会

官

方

A

P

P

第十一届中国国际石油化工大会合作伙伴——大连海密梯克泵业有限公司(简称:大连海密梯克)成立于1997年12月25日,由德国海密梯克泵业有限公司(HERMETIC-Pumpen GmbH)与大耐泵业有限公司合资创建。公司自成立以来,一直秉承德国质量与技术领先的管理理念,致力于无泄漏屏蔽泵及磁力泵的设计研发、生产制造、产品销售及售后服务工作。公司的无泄漏泵产品涉及21个系列、440个品种,被广泛应用于化工、石油化工、新能源、医药、纺织、核电站等领域。公司的年销售收入每年以近30%的速度稳步增长。大连海密梯克泵业有限公司作为第十一届中国国际石油化工大会的合作伙伴,将携手为大家带来无与伦比的化工行业盛会。本期将为您介绍海密梯克无泄漏泵替代传统离心泵案例。

由于屏蔽泵是一种拥有特殊结构的机电一体化设备,许多传统的泵类产品标准没有办法直接准确地覆盖和描述屏蔽泵的设计、制造和验收,这些因素导致了屏蔽泵在最早进入市场的时候无法被石化领域轻易的接受.

Because the Canned Motor Pump is a special electromechanical equipment, many traditional pump product standards can not directly and accurately cover and describe the design, manufacture and acceptance of the shielded pump, these factors led to the shielded pump in the earliest market can not be easily accepted in the petrochemical field.

随着外资屏蔽泵企业的进入中国市场,每个企业的屏蔽泵标准逐渐的成熟和得到了广泛的应用;同时美国石油协会(API)出版的一系列标准已被石化行业广泛接受,很好的弥补了市场对屏蔽泵的认知欠缺,也为无泄漏泵在石化领域的长足发展奠定了建设的基础.屏蔽泵在输送具有强腐蚀性、高温高压、有毒有害、易燃易爆、及低温等极端状态下的液体时有着非常大的优势;解决了在石化领域中长期困扰的输送难题.

With the entry of foreign-funded CMP enterprises into the Chinese market, the CMP standards of each enterprise gradually mature and widely used; At the same time, a series of standards published by the American Petroleum Institute (API) have been widely accepted by the petrochemical industry, which makes up for the lack of market knowledge on CMP and lays a foundation for the rapid development of Sealless pump in the petrochemical field. CMP in the transport of corrosive, high temperature and high pressure, toxic and harmful, flammable and explosive, and low temperature and other extreme liquid has a very large advantage; Solved the long - term problem of transportation in the petrochemical field.

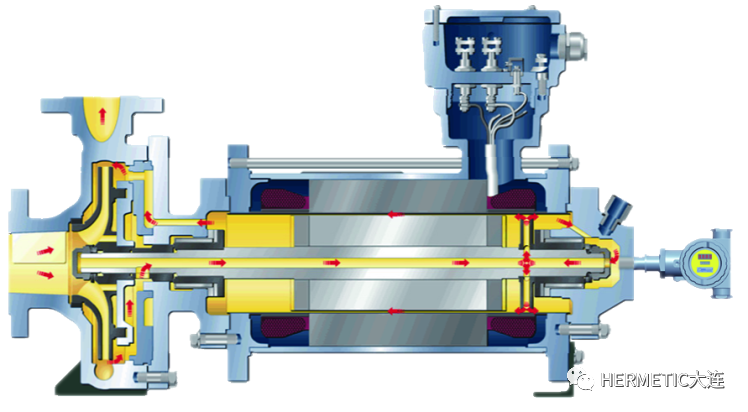

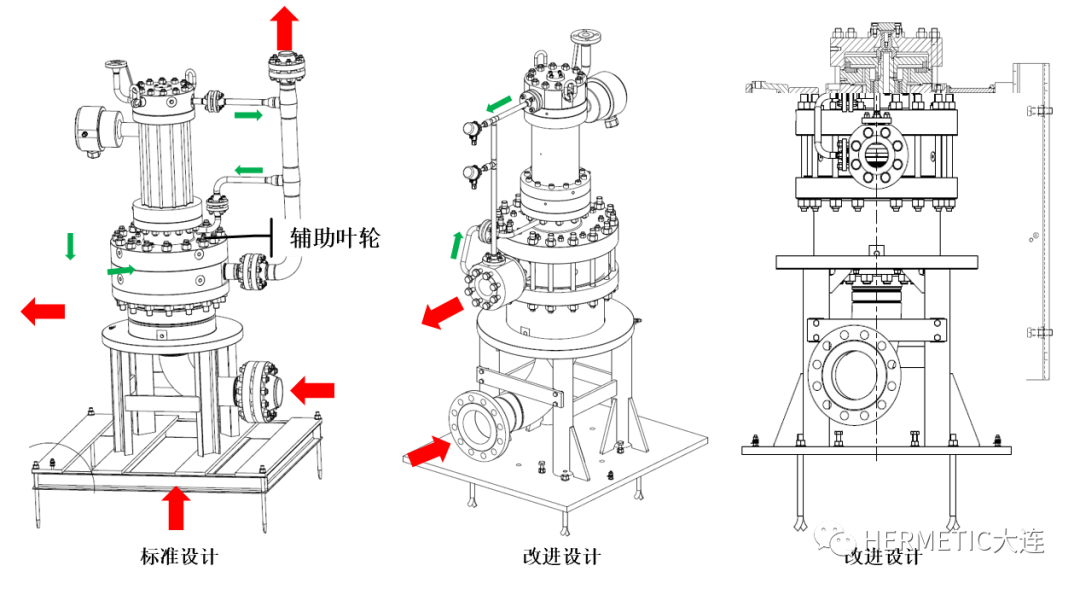

据分析,在石油炼化流程中超过50%的常规离心泵都可以被无泄漏屏蔽泵所取代,如常减压蒸馏、催化裂化(FCC)、加氢、脱硫、烷基化、气分、硫磺回收等装置中的大部分离心泵,甚至在加氢裂化装置中的部分应用中也有屏蔽泵的一席之地.如上图所示,是国外一工厂初期安装的,带机械密封的立式单级离心泵,运行一段时间出现密封系统故障、维护成本逐年上升、密封失效跑冒滴漏等现象.影响了正常的安全和生产进度.

According to the analysis, in more than 50% of the conventional centrifugal pump in oil refining process can be replaced by Sealless pump, atmospheric and vacuum distillation, catalytic cracking (FCC), hydrogenation, desulfurization, alkylation, gas and sulfur recovery device, even in parts of the hydrocracking unit has CMP in the application of a place. As shown in the above, is a factory installed in the early years of the abroad, vertical single-stage centrifugal pump with mechanical seal, running for a period of time, seal system failure, maintenance costs rise year by year, seal failure PaoMaoDiLou phenomenon. It affects the normal safety and production schedule.

海密梯克公司得到客户首选和认可,负责用屏蔽泵替代这台离心泵,其中需要最先考虑的就是介质的特性和现场原基础条件.

Hermetic has been approved by the customer and is responsible for replacing this centrifugal pump with a CMP

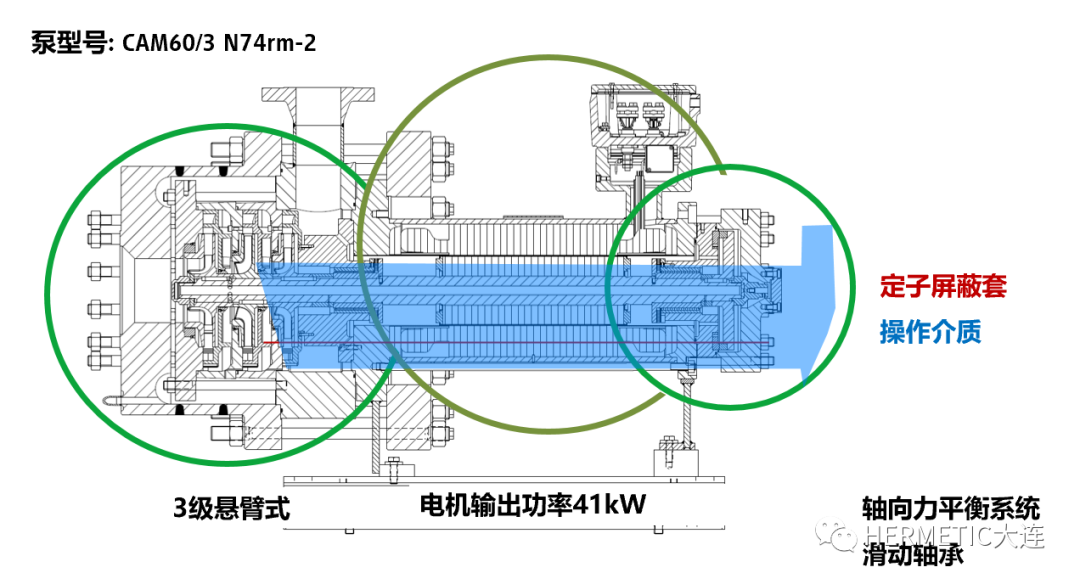

介质特性和工况需求海密梯克选择了三级屏蔽泵,输出功率41kW.

According to the characteristics of the medium and working conditions, Hamidytec chose a three-stage CMP with output power of 41kW.

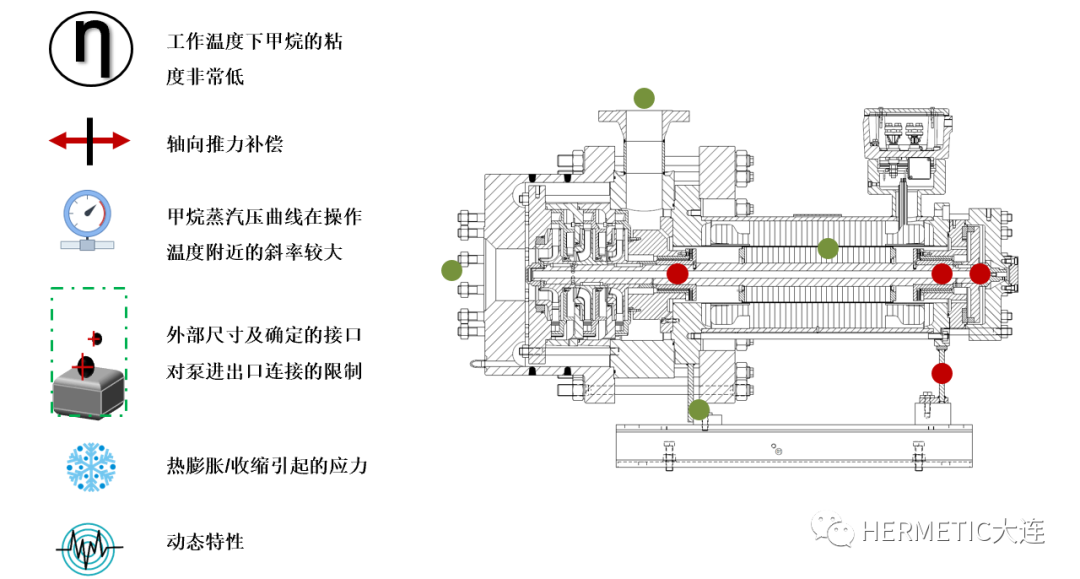

屏蔽泵选择之后,需要考虑以上几个问题,其中原有介质的低粘度的特性,则需要选用立式的屏蔽泵,保证轴承的使用寿命.

After the selection of CMP, the need to consider the above issues, the original medium of low viscosity characteristics, the need to choose the vertical CMP, to ensure the service life of the bearing.

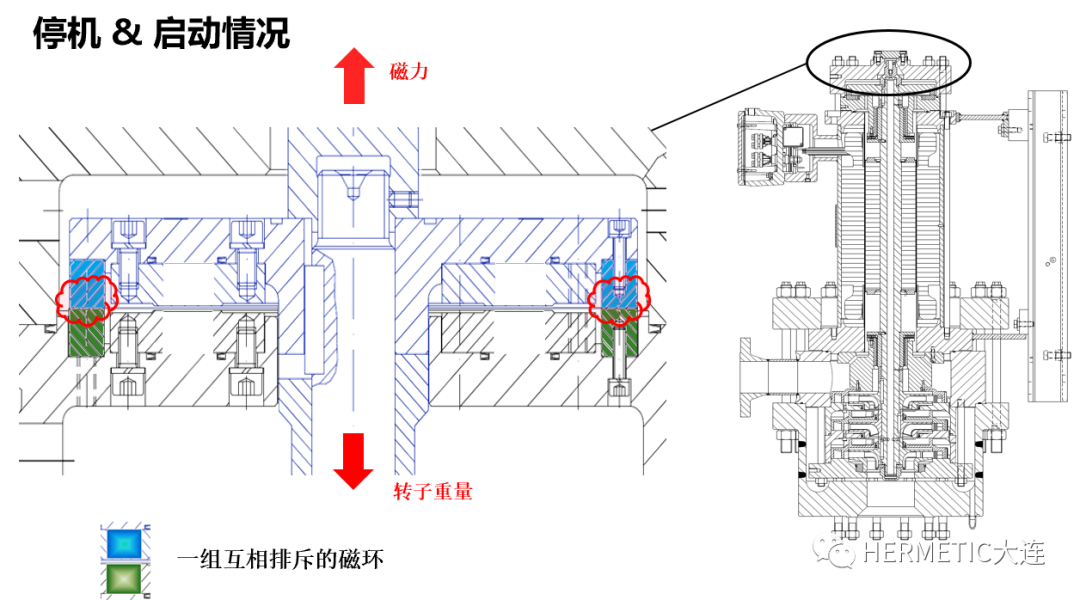

在泵正常运转时,平衡盘的动静环无接触.但是由于屏蔽泵设备的停机和再启动,平衡盘的动静环将相互接触的而受到磨损,为了解决这个问题,在上图的空白处加上一组互相排斥的磁环,保证在设备停机的时候平衡盘的动静环不会接触而相互排斥.

The pump running, the balance disc ring and static ring does not contact. But because of the CMP equipment shutdown and restart, ring and static ring will touch each other under wear, in order to solve this problem, in the above blank with a set of circular and repel each other, ensure that the equipment downtime, ring and static ring will not contact, but rejected.

由于限制于原来工况的现场布局,将管路改进设计如上图.

Due to the site layout limited to the original working condition, the pipeline design is improved as shown in the figure above.

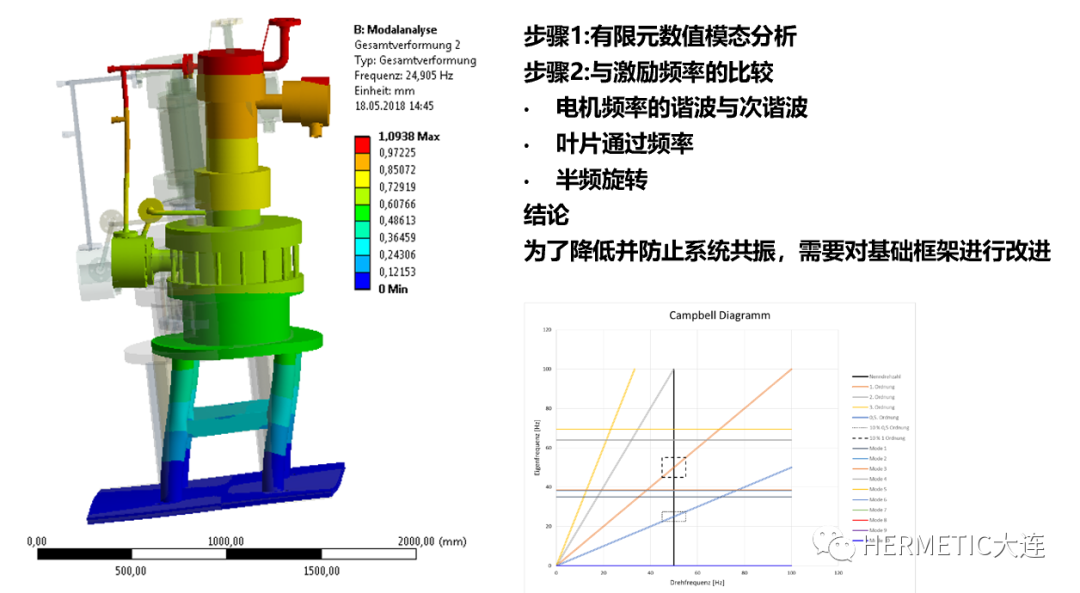

最后对泵进行热力学分析-热膨胀的测试-动力学分析.

Finally, the thermodynamic analysis - thermal expansion test - dynamic analysis of the pump.

最后通过分析\试验,达到了用户的需求标准,现场进行了安装.任务完成!

Finally, through analysis \ test, it reaches the user's requirement standard and is installed on site. Task to complete.

© 2025 CPCIC2025 www.cpcic.org All Rights Reserved.